Over the years, manufacturers have continuously introduced LED lamps to the market, with the ultimate goal of replacing incandescent lamps and compact fluorescent lamps (CFL). The design of these bulbs has evolved from a very simple non dimmable scheme to an expensive dimmable scheme to a more cost-effective dimmable scheme.

Many LED lamps claim to be dimmable, but in fact, the performance of many LED lamps is not very ideal, and the performance varies due to different dimmers and circuit loads. Sometimes, after the LED lamp is installed in the room with dimmer, the LED lamp will flicker and the brightness cannot be adjusted evenly.

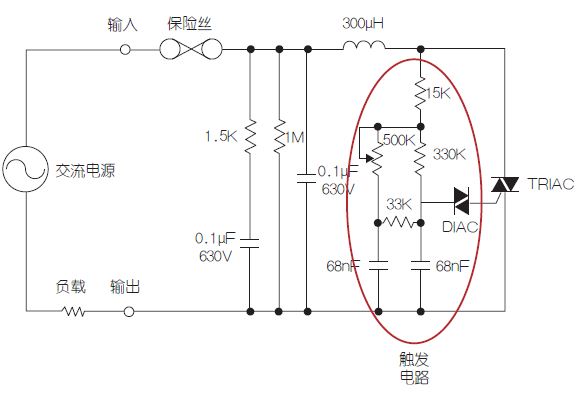

These defects are due to the fact that most dimmers used in the United States at this stage are based on bidirectional thyristor (triac) two-wire leading-edge phase cutting circuits, which were developed in the 1960s and are suitable for resistive incandescent lamps. Triac is a bidirectional semiconductor power switch, which is triggered by a pulse generated by a variable timing circuit and maintains conduction when the conduction current is higher than the holding current. There are many kinds of dimmer circuits, using devices with different characteristics, as well as different control circuits and filter elements.

The driver circuit of LED lamp converts the AC input power supply into low-voltage DC power supply, and maintains a stable current to drive the high brightness LED load to obtain a constant light output. If you want to adjust the basic LED driver circuit through the dimmer based on the bidirectional thyristor, you must add some additional components to achieve stable dimmer operation, and adjust the output current according to the dimmer phase angle.

Due to the large difference of dimmers, the performance of the connected led dimmer circuit is also different. As there is no clear standard to divide the performance of LED bulbs with dimmers, this problem becomes more complex. At most, some bulb manufacturers will provide a list of dimmers that they believe are compatible with their products.

With the support of the U.S. Department of energy (DOE), the American Electrical Manufacturers Association (NEMA) is working to develop dimming standards for LED lamps driven by phase-locked dimmers, including test procedures and indicators to determine whether acceptable performance is achieved. It is hoped that this standard will eventually help eliminate those products on the market that claim dimmability, but whose performance is far from the soft and stable products expected by end users, such as incandescent dimming.

Most LED bulbs use buck, buck, or flyback converters. In all cases, acceptable dimming performance can be achieved by modifying the basic circuit without increasing the cost and complexity of the device. In this way, the performance of the dimmable driver can be improved, so as to meet the cost saving requirements of the consumer lighting market.

The problem of compatibility is how triac dimmer circuit interacts with LED driver input circuit.

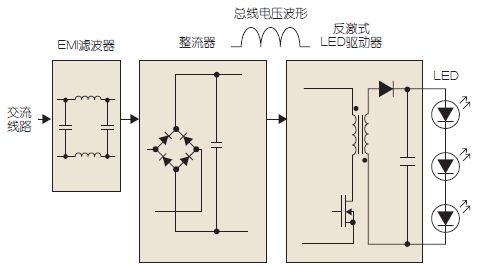

The single-stage LED driver example circuit (Figure 2) replaces the resistive load representing the incandescent lamp in Figure 1. Although this circuit simulates resistive load due to its high power factor in stable operation, its front end also includes capacitors necessary for filtering. In addition, LED bulbs consume less power than equivalent incandescent lamps by 25%. As a result, before triac triggering, the dimmer mainly bears capacitive load in the half cycle of AC line.

Figure 1: schematic diagram of a typical dimmer

How to make LED bulb dimmable

Figure 2: basic LED driver circuit block diagram

If the bidirectional trigger circuit shown in Figure 1 wants to operate according to the design goal, it also needs a resistive path to the neutral point. If it is changed to capacitive load, this circuit will not operate normally, and lead to unstable triggering during cycle conversion, which is manifested in the continuous flashing of output light. EMI filter in dimmer and LED driver will also cause ringing oscillation due to high dv/dt when triac is started.

When the oscillation amplitude reaches a certain degree, it will cause the current to fall below the "hold current", so that the triac is closed, and the triac cannot be maintained on before the lower line crosses zero. In this case, the trigger circuit usually triggers triac again, causing it to open and close multiple times in a single line half cycle. In addition to causing stress to the components and likely to damage the dimmer or LED driver, this will lead to serious flickering and unpleasant noise.

Assuming that using the dimmer suitable for LED lamps to replace the dimmer is not an ideal solution, the above problems can be solved by modifying the LED driver, so as to realize the combination of LED driver and standard dimmer.

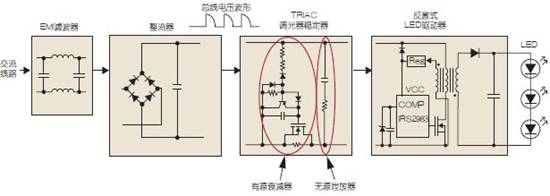

Figure 3: schematic diagram of dimmable LED drive.

How to make LED bulb dimmable

The example circuit (Figure 3) is a single-stage led flyback converter, and the same technology can also be used for voltage rise and fall or adaptive step-down converters. First of all, the input capacitance must be kept at the value when designing the input filter, which is also conducive to the realization of the power factor.

The next step is to introduce the active attenuator and passive bleeder circuits. The attenuation circuit will limit the impulse current when the triac is triggered, so as to greatly suppress the ringing, so that the triac remains in the on state. After a short time delay, the attenuation resistor is bypassed by a small MOSFET to prevent power loss during the remaining conduction period. In order to reduce the cost of low-power drivers, bypass MOSFETs and their related can be ignored, but this will lead to heat dissipation of resistors and related efficiency losses.

Passive bleeder circuits can be used instead of active bleeders used in some dimming solutions. The series RC network conducts current from the trigger point, and the time is enough for the switching converter to start extracting current, which helps to ensure that the current does not fall below the holding current during this period. Flyback or voltage rise and fall converter operating with constant conduction time as the main resistive load connected to the DC bus can maintain the conduction state of the dimmer triac before the next line zero crossing. The converter needs to draw enough current to maintain above the triac holding current. Single stage PFC flyback or boost boost converter can usually achieve this goal.

The circuit described here adopts irs2983 controller IC, which operates in voltage mode. The DC voltage level at the comp input determines the on time of the switching cycle. Because the controller IC is often used with the primary side regulation to maintain a constant output power, it is necessary to add a zener diode on this input to clamp the comp voltage. This limits the on time, so that when the DC bus voltage drops during dimming, the on time cannot be increased to compensate.

As a result, the output current will decrease as the dimmer setting decreases and the DC bus voltage decreases. In this way, the light brightness can be adjusted to less than 20% by adjusting the dimmer control without using a more complex circuit to detect the dimmer phase angle or adjust the output. At the same time, the VCC power supply of the controller must be released during the dimming shutdown to ensure that the IC operates only for the required period of time. For this purpose, a high-voltage diode is used to connect VCC and DC bus.

Active attenuator and passive bleeder circuits can also be used with step-down converters, but the result depends on the LED voltage. Because the converter cannot draw current when the line voltage is lower than the output voltage, the operating range of phase dimming will be limited. For this reason, the LED voltage should be kept low, but it should not be too low, otherwise the circuit will become invalid and too large inductors need to be used. For a 120VAC system that maintains a reasonable adjustment range, the LED voltage is 20V ~ 40V. CCM step-down LED controller IC (such as irs2980) can maintain the average current regulation of LED lamps while the uneven bus voltage is always higher than the total output voltage of LED.

These simple techniques introduced in this paper, when used with the LED converter described above, can make most triac based dimmers achieve smooth dimming without flicker.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is infringement or objection, please contact us to delete. thank you!

中恒科技ChipHomeTek

|